In my continuous search for material for this publication, I run across all kinds of interesting people and ideas. There are some really creative folks out there, people who think outside the box and come up with innovative solutions. The history of broadcast engineering has quite the cast of such people.

Way back when (here he goes again!), on-air phone systems were non-existent and usually consisted of a modified speakerphone … that is until a guy named Steve Church came up with an idea for hybrid interface to the then-ubiquitous 1A2 phone system. That’s one of the best examples of smart people in broadcast engineering coming up with an innovative solution that I can think of, although there are many more.

In the decades since, a good number of niche broadcast equipment manufacturers have come out with an array of purpose-specific products. Companies like Broadcast Tools, Inovonics, Radio Design Labs, Henry Engineering and Angry Audio come to mind, although that’s nowhere near being an inclusive list.

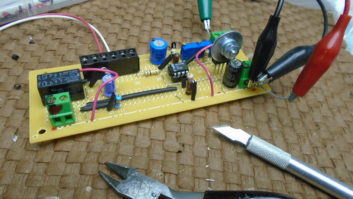

But prior to the availability of ready-built gizmos that perform special functions, quite often we built our own; and many broadcast engineers still do that sort of thing.

In my earliest days in radio, I remember watching the chief engineer at the AM/FM combo in his shop, huddled over a smoking soldering iron and building up a gadget to do … something or other.

Time tones

It wasn’t long after I moved into the technical end of things that I started doing that kind of thing myself, and with it came the deep satisfaction of creating from a pile of parts a gizmo or gadget to make someone’s life easier in the radio station.

One of the most interesting (read: weird) gizmos that I was called upon to create was a time-tone generator.

The Dallas top-40 FM where I was CE in the very early 1980s hired a programming consultant to get those extra few tenths of a point in the ratings, and in one of his first visits to the station, he told me that we had to have a tone that would come over the air at the exact top of every hour. Evidently that was somehow of critical importance to listeners.

With raised eyebrow, I nodded my understanding and I set to work building up a device that generated three distinct tones of specified frequencies that someone’s research had determined were the best attention-getters.

I used an ESE precision clock to gate the three tones into the audio mix for one second at the top of every hour, and it worked like a hose. The tone-trio blasted through the music like a train horn, and the consultant was happy.

We ran that thing for the better part of a year. I don’t recall if it helped or hurt the ratings, but I can speculate that it didn’t help. It was obnoxious!

The point is, even in today’s broadcast technical environment where we have many options and sources for every kind of gadget under the sun, once in a while, you’re going to run into a need for something that you can’t buy off the shelf. And that’s where we get to do some real engineering and show our stuff.

Affordable fix

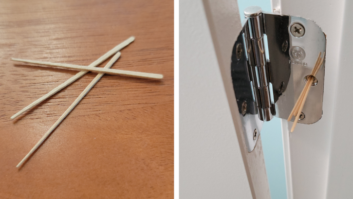

Sometimes this kind of thing takes the form of finding innovative ways of using off-the-shelf equipment to perform tasks for which it was not really intended.

In one of Crawford Broadcasting’s Midwest facilities, our engineering staff employed GPIO logic in the AoIP system to provide remote control of facility security features, such as the electric gate providing parking lot access, all without running a single wire through the ceiling.

Other times, perhaps a purpose-built device is available but there’s no budget for that item. In those cases, we may be called on to build up a gizmo ourselves. Nothing wrong with that.

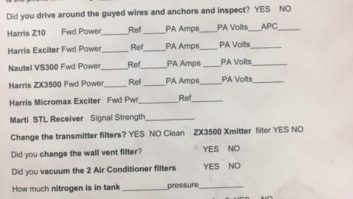

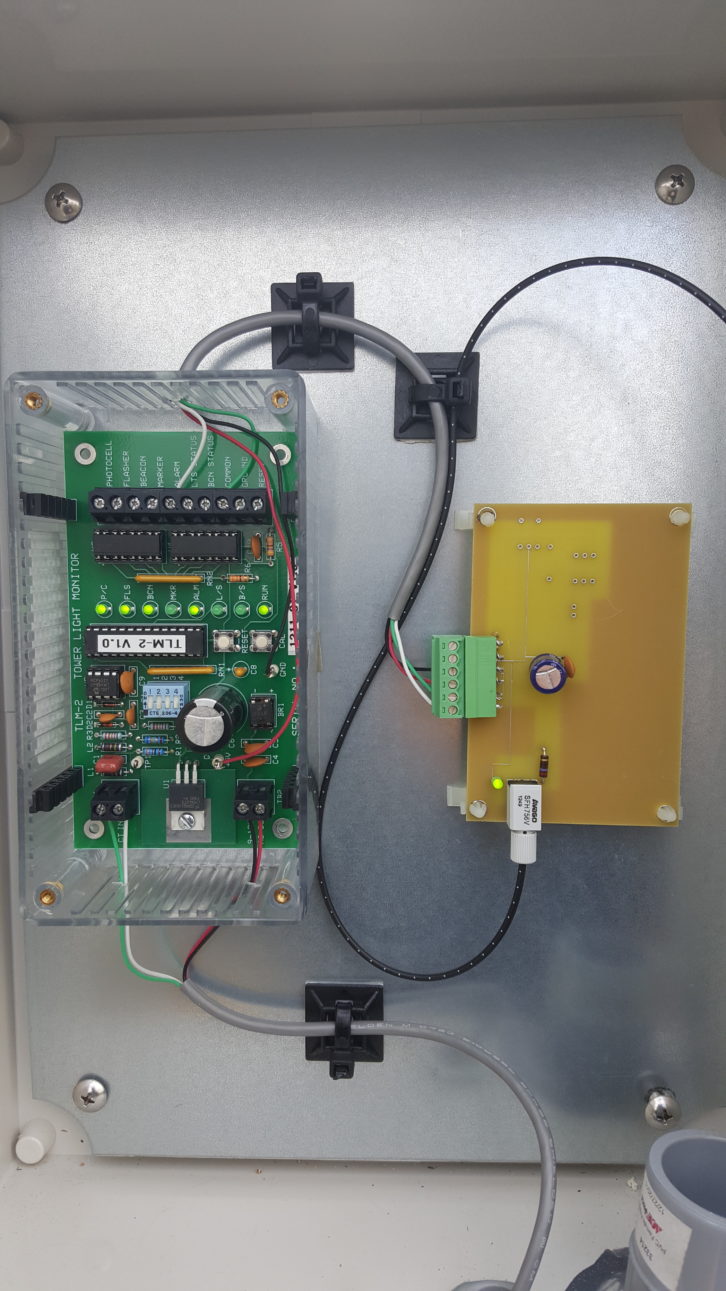

A decade ago, as we started converting to LED lighting systems on our AM towers, we needed a way to get alarm and status contacts across the tower base insulator so that they could be monitored remotely.

There were purpose-built fiber-optic devices available, but they were expensive, and we were talking about a lot of towers. So I went on www.mouser.com/ and found fiber-optic transmitter and receiver modules, I had some PC boards printed using one of the services featured in these pages in months past, and with a handful of resistors, capacitors, LEDs and opto-isolators, we rolled our own.

They too work like a hose, and all for about $20 per tower. Those devices are still in use all over my company.

In this issue

The latest issue of RW Engineering Extra is out.

My longtime friend and colleague Buc Fitch is an old-school home-brewer. He loves to design and build gadgets, and in this issue, he will share with you his design/build project of a thermal sensor and temperature alarm. This is a great example of what broadcast engineers do on a routine basis, and we hope that the circuit is something you can use… and modify to fit your specific application.

We’re also going to start a new educational series in this issue. Dennis Sloatman will over the next few issues teach us what we need to know about three-phase power. Most all of us use equipment that employs 208-, 240- or 480-volt three-phase power, but what do we really know about it? What do we need to know about it? I know you’ll enjoy Dennis’s approach to this topic, and I guarantee you’ll learn something.

Meanwhile, the next time you run into a special need at one of your radio stations, you might think about taking a walk on the wild side and rolling your own. You’ll get a lot of satisfaction out of creating a purpose-built device of your own to meet that need.