In the first two installments of this series, we discussed whether or not an old transmitter was even worth fixing, followed by some techniques I�ve used to repair high-voltage power supplies. This time, we�ll talk about control circuitry.

As I wrote last time, working with transmitters that use any kind of high-voltage (whether AC or DC) is inherently dangerous. Never work on transmitters when alone or tired. Take every precaution, and then take every precaution again.

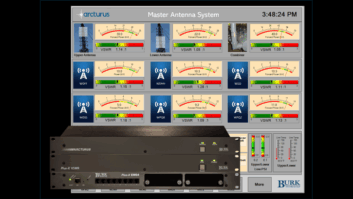

Click to Enlarge Control circuitry was designed to accommodate vacuum tubes.

For the purposes of this article, �old� means the transmitter uses vacuum tubes. You could also be restoring an early solid-state transmitter; some of what I�m writing will apply to that sort of project as well.

To operate the transmitter, and especially to accommodate the vacuum-tube amplifier, older transmitters use relay logic, more typically known in broadcast engineering as a �control ladder.� Essentially what you have is a string of relay contacts, each of which must be closed in order for the transmitter to come up (meaning that the HV power supply will be energized).

Logically, you could consider the control ladder to be a multi-input AND gate: Each and every input must be high, and only then will the output go high, thus �turning on� the transmitter, causing it to generate RF.

The �ladder� notion comes in to play because the various logic states occur in order, and as one �rung� is completed, the next one is examined. With each correct logic state, the ladder is climbed, the end result being that the transmitter comes up. A typical sequence would be as follows:

Blower is energized. Once the blower is energized, an air pressure switch is closed. This is the bottom rung of the ladder.

Click to EnlargeFilament/heater is energized. The relay logic allows the filament (or heater) to be energized with appropriate cooling, as determined by the air pressure switch.

Filament delay. Some sort of time delay will be used to prevent the application of HV prior to a warm-up period. This is the next rung up.

Bias power supply. The vacuum-tube amplifier will be biased with a control-grid power supply so that the static current drawn through the tube (without any kind of RF amplification) is at a safe level for the tube. This power supply must be present.

Overloads are not set. Overload relays are rudimentary current detectors designed to prevent over-current conditions in the transmitter. When overload relays energize, they open the interlock chain, de-energizing the HV power supplies.

Interlocks are closed. The relay logic is designed to prevent the application of any HV power supplies if it detects that the interlock string is open. The interlock string will include all doors and the external interlock, which is used to determine that an antenna or dummy load is connected to the output of the amplifier. This is the top of the ladder.

Not every single vacuum-tube design is the same, but you�ll find, after examining the schematic (which you must have) that they all work in a very similar fashion. If all those conditions are met, the transmitter is ready to be turned-on (i.e., the HV power supplies can be energized).

PROBLEMS ENCOUNTERED

Ninety percent of the problems encountered with the control ladder will be related to the following items that wear out over time:

Pushbuttons. As I mentioned in the first of this series, make sure you can find a suitable replacement. That doesn�t necessarily mean an exact replica of the original.

Click to EnlargeBad relay contacts in control ladder. One thing to look for with relays that don�t �latch� is for pitted �latching� contacts. Make sure replacement relays, if not identical, can withstand the open contact voltage, as well as the current expected to pass through the contacts.

Blower is ineffective. Make sure squirrel-cage blades are clean, and free of dirt. Replace bearings in the blower motor, or perhaps the entire motor, as warranted.

Air pressure switch. Make certain this works correctly. Low, or no air pressure, must keep it from closing. You could test this by very carefully blocking the airway in to the blower with a piece of cardboard as it is running (HV power supplies OFF, of course).

Interlock contacts are open. Interlocks can be open, thus keeping the logic from turning on the HV power supplies. Also look for interlocks that are stuck closed; this can be a very dangerous situation, potentially keeping the HV power supplies energized, even when a door is opened.

Overload relays are too sensitive. Likely you would discover this once other aspects of the control ladder are made operational.

Always trouble-shoot a control ladder from the bottom up. The other 10 percent of possible problems may require more of your troubleshooting skills: Look for open wires within bundles (using an ohmmeter); burn marks; or other modifications (�kludges�) that may represent changes in the circuitry. I recommend removing modifications and restoring the original circuits.

Next time: the RF amplifier deck.