BELLINGHAM, Wash. —Miles and miles of old analog wiring have been pulled out in favor of Cat-6 runs; consoles have become control surfaces with no actual audio passing through them; racks where distribution amplifiers and switchers lived for many years are now filled with blank rack panels; and instead of inputs and outputs we are thinking more in terms of sources and destinations. Cascade Radio Group has recently gone digital with WheatNet-IP audio networking.

CRG is a group of five radio stations owned by Saga Communications. KISM(FM) (classic rock), KAFE(FM) (Today’s Variety), KGMI(AM) (news/talk), KPUG(AM) (sports) and KBAI(AM) (progressive talk) operate from one facility in Bellingham, Wash. We have five on-air studios and two production rooms. The addition of WheatNet-IP has streamlined our facility, making configuration and troubleshooting faster and easier.

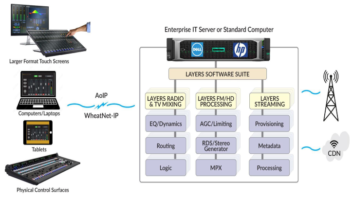

Our WheatNet-IP system consists of two core switches, to which edge switches are connected in each studio. Every Blade I/O network access unit and PC driver’s NIC is either plugged into an edge or core switch, depending on their location. Dual NICs are used on computers that utilize Wheatstone’s PC driver to stream audio in and out of machines, one NIC for the automation network and the other for WheatNet-IP. The PC drivers show up in the system’s Navigator software like a Blade would, allowing us to crosspoint audio to and from them easily. Once the audio sources are “in the system,” those sources are then routable anywhere in the network. This gives even our production studios the ability to go “on air” with just a few crosspoint changes.

We utilize 24 Blades of various models (IP88A, IP88AD, M4 and Mix Engine) to route audio and logic functions in and out of studios, as well as in the master control room to handle audio and logic for our 12 satellite receivers. Six of the eight Blades in master control handle the satellite audio and contact closures for all five stations. Contact closures are wired directly into the logic ports on Blades and are defined as an LIO source. Once an LIO is defined it can be converted to an SLIO by making a single crosspoint and either defining a user function name or using a pre-defined function via Navigator.

NETWORK

Our automation system, iMediaTouch by OMT, only recognizes SLIOs, so all satellite contact closures that the automation uses have to be converted from the physical LIO to an SLIO. IMediaTouch uses SLIOs defined in the On Air module to make or break satellite connections, fire liners from the automation’s show log page and also to turn the satellite fader on/off on the control surfaces. It’s always gratifying to see the iMediaTouch system make the satellite audio connection and turn the fader on when the feed starts. Likewise, when the feed ends, the audio connection breaks and the channel turns off. Logic circuits to control on air lights, mutes and remote starts are wired into the IP88A Blade in each studio, keeping control local for each studio.

We have a combination of Wheatstone E-6 and Audioarts IP-12 control surfaces in our studios. Each surface is essentially a big smart mouse. Both series of surfaces are a breeze to use. Sources are easily assignable to faders. Programmable buttons assigned to switch “Events” can reconfigure the whole surface to a user’s preference with the press of a button. We have assigned two buttons on each on-air surface to control the “Next Event” and “Talk Break” functions in the automation system for easy access for the talent.

There is one lonely analog console left in the building. It’s an Audioarts D-75 that resides in our smallest production studio (Production C). In this studio an IP88a Blade is used to route audio in and out of the room. Since we have an automation utility machine in the room that is on WheatNet-IP, multiple instances of Wheatstone’s PC-XY application have been installed on that machine. PC-XY allows users to select sources quickly by scrolling through the source and destination menus and clicking “take” once that information has been defined, much like their XYE-R controller. There are also eight user-definable buttons per instance of the application, making quick source selection faster. In Production C each instance of the app is pointed to its own channel on the D-75, essentially creating an A-H source select per channel, switchable with the click of the mouse. The PC-XY application has increased the usability of this studio immensely as any source in the WheatNet-IP system can be pulled up with ease.

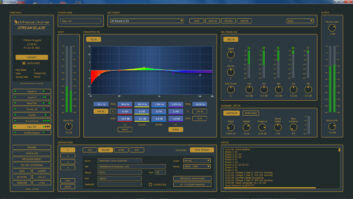

One of the most powerful tools at our disposal is a laptop loaded with Wheatstone’s Navigator and GUIs for configuring IP-12 surfaces/Mix Engines, setting and tweaking the M4-IP four-channel mic processors, and other GUIs for setting the Aura8-IP Blade multimode processing where needed. Going into a studio to troubleshoot or tweak levels has just a matter of plugging the laptop into the WheatNet-IP edge switch and opening whatever app that’s needed. With Navigator, we have our whole system configuration at our fingers.

WheatNet-IP has been stable since installation and maintaining the network has been easy.

For information, contact Jay Tyler at Wheatstone in North Carolina at (252) 638-7000 or visit www.wheatstone.com.